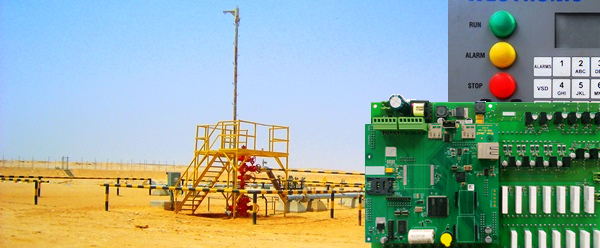

Components of electric drives for electric submersible pumps (ESP)

MMB Drives Company performs R & D development for the oil industry, including digital control systems, controllers work, advanced cooling systems, inverter type Active Front End Drive pump oil medium voltage (MV) and low voltage (LV). Our products are designed for operation in ambient temperatures up to 55 degrees Celsius.

Typical electrical submersible pump (ESP) installed on the oil field contains a three-phase squirrel cage induction motor special adapted to the diameter of the opening of the shaft (usually 18 - 25 cm) ,seal section, multi-stage centrifugal pump with rotor, gas separator optional, electrical cable with a length of 1 - 5km and located on the surface of the power electronics inverter of the transformer providing galvanic isolation from the mains. ESP motor voltage drives is selected from the range of 415V to 5kV, depending on the capacity of the drive. Due to the lack of standardization of oil pump drives voltage levels in the oil fields are installed transformers with tap changers . A single high power ESP system drive, may have a yield of up to 1000 barrels per day. When using motors and cables made of special materials pumps can operate at a temperature in the shaft mining reaching up to 230 degrees Celsius.

Among other types of oil pump systems, ESP drives have a shorter life and require regular replacement of components, surge protection systems and short circuit detection systems due to the higher risk of aging of insulation in high temperature shaft.

In 2008 MMB Drives Ltd started mass production and has exported components for the oil pump drives, including:

- Back Spin Relays ...read more.

- Back Spin Voltage Dividers ...read more.

- TEC cooling modules.

- 1500W power supply with adjustable output voltage 24V - 48V and a wide range of input voltage changes, including to power cooling systems.

- Motor controllers (MCs).

Since 2013 MMB Drives Ltd has had in its offer active-front-end power converters for ESP drives:

- Bi-directional converters 3.3 kV medium voltage, 600kW of an Active Front End Seal implemented on high-frequency dc-link - do not require the use of a bulky line-frequency transformer from the network ...read more.

Technical Informations and orders:

- email: info@mmb-drives.com.pl

- mobile: +48 605-068-292

Scroll

to top